Metal And Ceramic Injection Molding Market: Global Share, Size, Growth, Trends & Outlook ( 2023 – 2032 )

Metal And Ceramic Injection Molding Market Insights:

Metal and ceramic injection molding (MCIM) is a producing method that mixes the benefits of both metal and ceramic materials to produce convoluted, high-precision components. The system involves injecting a mixture of metallic or ceramic powder and binder right into a mold, when it is then heated and cooled to solidify the material. Powder injection molding (PIM) is an advanced manufacturing manner that utilizes metallic and ceramic injection molding techniques to provide elaborate and massive-scale components. These innovative techniques are relatively powerful in streamlining high-volume manufacturing and attaining convoluted designs.

Metal And Ceramic Injection Molding Market Size

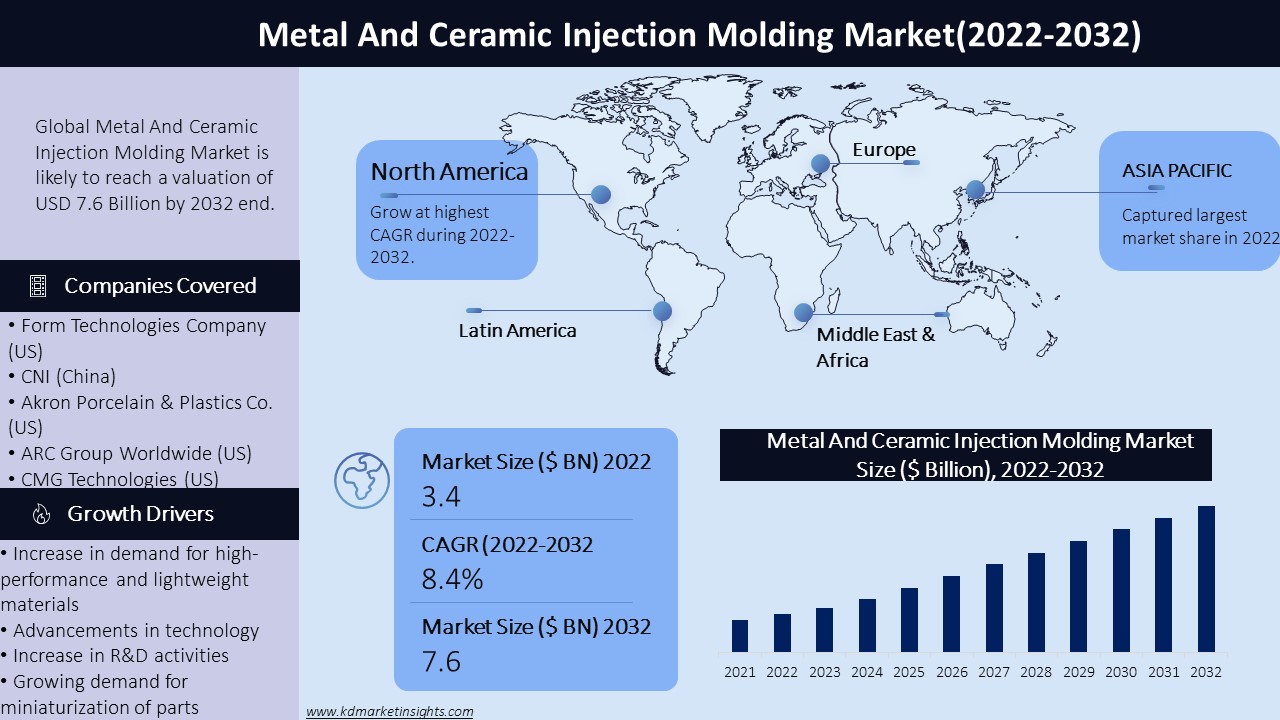

The global metallic and ceramic injection molding marketplace is expected to grow at a great rate due to increasing demand for high-overall performance and light-weight substances in various industries together with automotive, aerospace, medical, and electronics. Factors inclusive of advancements in era and growing R&D activities to expand new substances and applications are consequently expected to force marketplace growth. The global metal and ceramic injection molding market was worth approximately $3.4 billion in 2022 and is expected to reach $7.6 billion by 2032, with an 8.4% compound annual rate of growth (CAGR) throughout the forecast period (2023-2032). Asia-Pacific is anticipated to dominate the market due to increasing call for light-weight materials inside the automobile and electronics industries in countries consisting of China, Japan, and South Korea.

Metal And Ceramic Injection Molding Market: Report Scope |

|

|

Base Year |

2022 |

|

Base Year Market Size |

$3.4 billion |

|

Forecast Year |

2023-2032 |

|

Forecast Year Market Size |

$7.6 billion |

|

CAGR Value |

8.4% |

|

Segmentation |

|

|

Challenges |

|

|

Growth Drivers |

|

Metal And Ceramic Injection Molding Market Driving Factors

There are several factors driving the growth of the metal and ceramic injection molding market:

- Increase in demand for high-performance and lightweight materials: The growing demand for light-weight materials inside the automobile and aerospace industries is one of the important elements driving the market growth. Metal and ceramic injection molding is used to produce high-overall performance and lightweight parts this is capable of face up to excessive temperatures and stress.

- Advancements in technology: The improvement of advanced technology which includes computer-aided design and simulation, and automation are driving the marketplace growth. These technologies allow manufacturers to provide convoluted and high-precision parts with improved performance and decreased manufacturing time.

- Increase in R&D activities: Companies are investing heavily in Research and Development sports to develop new materials and applications for metal and ceramic injection molding. This is predicted to Increase the demand for steel and ceramic injection molding in diverse industries.

- Growing demand for miniaturization of parts: The miniaturization of parts is a growing movement in the electronics and medical device industries, which is driving the market growth. Metal and ceramic injection molding is used to produce diminutive and convoluted parts with high precision.

- Cost-effective method of production: Metal and ceramic injection molding is a cost-effective method of production, as it allows manufacturers to produce convoluted parts with high precision at a lower cost compared to traditional manufacturing methods.

Metal And Ceramic Injection Molding Market Key Trend & Development:

There are several key trends and development in the field of the Metal and Ceramic Injection Molding Market:

- Technological advancements: Technological advancements in MIM and CIM have enabled the production of more convoluted components with higher precision and consistency. The utilize of advanced materials and processes has therefore improved the properties of MIM and CIM components, such as their strength, wear resistance, and corrosion resistance.

- Increased emphasis on performance and sustainability: Manufacturers are striving to become more sustainable, and MIM and CIM are viable options for producing environmentally amiable products. Injection molding is capable of reduce emissions by means of reducing the request for conventional manufacturing processes such as stamping and machining. Additionally, injection molding can create lighter-weight items than traditional manufacturing methods, reducing environmental impact.

- Adoption of 3D printing technology: Increasing adoption of 3D printing technology in various industrial applications is one of the major factors driving the growth of the MIM and CIM market. The global spending on 3D printing solutions is expected to increase, which will drive demand for advanced engineering solutions such as those offered by means of MIM and CIM products.

- Rising demand from emerging markets: Many companies are turning to injection molding to meet the growing demand from emerging markets such as China and India. These regions are in process of rapid growth, driving accelerated consumer demand for items starting from cars to electronics. Injection molding lets in manufacturers to rapidly produce superior goods.

Metal And Ceramic Injection Molding Market Segmentation

The metal and ceramic injection molding market can be segmented based on the following:

- By Material

- Iron and Steel

- Stainless Steel

- Superalloys

- Alumina

- Zirconia

- Materials

- By Application

- Medical & Healthcare

- Industrial Machinery

- Consumer Products

- Automotive

- Aerospace

- Other Applications

- Region

- North America (U.S., and Canada)

- Europe (U.K., Germany, France, Italy, Spain, Russia, NORDIC, Rest of Europe)

- Asia-Pacific (Japan, China, India, Indonesia, Malaysia, Australia, Rest of Asia-Pacific)

- Latin America (Mexico, Argentina, Rest of Latin America)

- Middle East and Africa (Israel, GCC North Africa, South Africa, Rest of the Middle East and Africa)

Metal And Ceramic Injection Molding Market Regional Synopsis:

North America is anticipated to be the fastest developing region due to due to the rising usages of advanced technology for metal and ceramic injection molding. By 2032, the market is predicted to be worth $2.01 billion, growing at a CAGR of 9.0% (2023-2032) against an earlier estimation of worth $850 million in 2022. With the USA serving as the region's largest market

Europe is another important marketplace for Metal And Ceramic Injection Molding. The presence of major manufacturing companies within the region has an impression on the market. By 2032, the market is predicted to be worth $1.12 billion, growing at a CAGR of 8.2% (2023-2032) against an earlier estimation of worth $510 million in 2022.

Asia-Pacific dominates the metal and ceramic injection molding market in terms of market share and revenue during the forecast period. The region's primary markets are Japan, China, and India. With a CAGR of 8.5% (2023-2032), the market is predicted to succeed in $3.07 billion by 2032 against an earlier estimation of worth $1.36 billion in 2022.

Although the marketplace for Metal And Ceramic Injection Molding in Latin America is comparatively small, it's anticipated to expand significantly within the coming years. With a CAGR of 8.3% (2023-2032), the market is predicted to succeed in $905.6 million by 2032 against an earlier estimation of worth $408 million in 2022.

The Middle East and African marketplace for Metal And Ceramic Injection Molding is relatively small, but it's expected to grow within the coming years because the region's manufacturing infrastructure gets better. By 2032, the market is predicted to be worth $587.3 million, growing at a CAGR of 8.0% (2023-2032) against an earlier estimation of worth $272 million in 2022.

Metal And Ceramic Injection Molding Market Challenges

There are several challenges facing the metal and ceramic injection molding market:

- High initial investment cost: Starting a metal and ceramic injection molding project is capable of be an enormous financial investment. The equipment and tools required for the process can be costly, especially for smaller businesses.

- Lack of skilled labor: Skilled labor is key to achieving success in the metal and ceramic injection molding process. Unfortunately, finding workers with the necessary expertise can be a challenge, given the limited pool of skilled laborers.

- Cost of raw materials: The cost of raw materials is a significant factor to consider in the metal and ceramic injection molding processes. Metal and ceramic powder costs might be unusually high, growing businesses general cost of manufacturing.

- Complexity of the process: The process of metal and ceramic injection molding is convoluted and requires precise control of the molding parameters, making it a challenging for manufacturers

- Environmental concerns: Manufacturing companies may be concerned about waste and harmful substances that the metal and ceramic injection molding process can produce since they may be hazardous to the environment.

- Quality control and consistency: Manufacturers face a significant challenge when it comes to quality control and consistency in the metal and ceramic injection molding process. The complexity of the process can make it difficult to achieve consistent results and maintain quality control throughout production."

- Scaling up production: Scaling up production from small-scale laboratory to commercial scale can be a daunting to manufacturers in the metal and ceramic injection molding work. The convoluted nature of the process and the request for precise control of the molding parameters make this a challenging undertaking.

Metal And Ceramic Injection Molding Market Key Players

There are several key players in the metal and ceramic injection molding market, some of them are:

- Form Technologies Company (US)

- CNI (China)

- Akron Porcelain & Plastics Co. (US)

- ARC Group Worldwide (US)

- CMG Technologies (US)

- PSM Industries (US)

- NIPPON PISTON RING Co Ltd. (Japan)

- ABBOT Furnace Company (US)

- Morgan Advanced Materials (UK)

- ARBURG GmbH + Co KG (Germany)

- Ortech Advanced Ceramics (Us)

- Epsom Atmix Corporation (Japan)

- INDO-MIM (US)

- Britt Manufacturing Company (US)

- Cypress Industries (US)

- AMT (China)

- GKN Powder Metallurgy (US)

- PTI (India)

- Smith Metal Products (US)

Need Customized Report for Your Business ?

Utilize the Power of Customized Research Aligned with Your Business Goals

Request for Customized Report- Quick Contact -

- ISO Certified Logo -